Sugar

Frequently Implemented Processes

- Cleaning

- Aquaeous extraction

- Lime-carbonic acid equilibrium

- Concentration

- Crystallisation

- Centrifugation

- Drying

- Storage silo

- Packaging, Labelling

- Water treatment

- Effluent treatment by anaerobic digestion

- Energy recovery from biomass

- Dust collection

Some of our Achievements

-

Compagnie Sucrière Sénégalaise

Construction of a thermal power plant on bagasse fuel.

-

Cristal Union

New beet washing skid.

-

Cristal Union

Dehydration skid fed by a biomass stove for drying organic alfalfa, beet pulp and sawdust.

-

Eurodia

Ion exchange and microfiltration units for glucose syrup production.

-

Féculerie d'Haussimont

Renovation of the extraction workshop and the protein factory from potato skins.

-

Lantic Rogers

Process optimisation in 3 plants, sugar cube and powder packaging, raw material receiving, dust collector and lime waste filtration.

-

S.V.I. Sucrerie de Sainte Émilie

Increased on-site storage capacity with flat horizontal silo and laminated timber frame.

-

S.V.I. Sucrerie de Sainte Émilie

Renovation of the 1st jet turbine and cooling drying workshops.

-

Saint Louis Sucre

Capacity increase and energy reduction of brown sugar production.

-

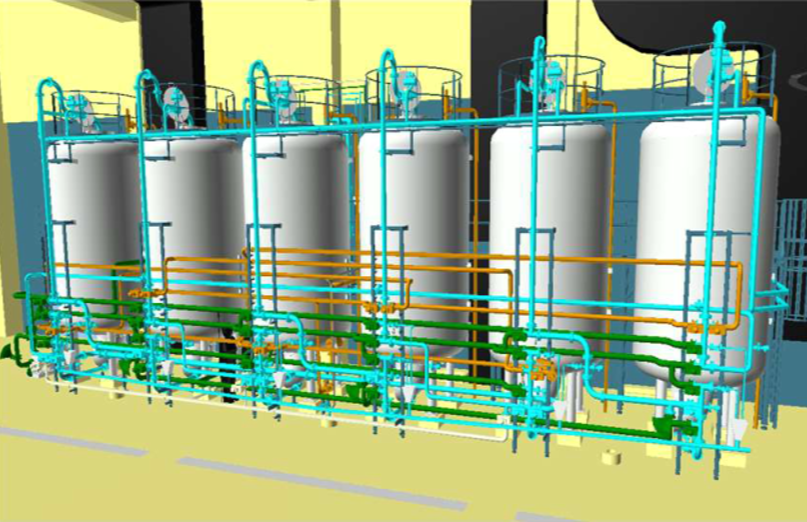

Sucre liquide

Multiple projects for receiving, storing and distributing liquid sugar in food plants.

-

Sucrerie d'Olmedo

Adaptation of beet processing skid to brown sugar refining.

-

Sucrivoire

Installation of a condensing turbine generator in a sugar facility.

-

Tereos

Modification of the diffusion, purification and evaporation workshops for energy savings purpose.

-

Tereos

Modification to the thermocompression station of the evaporation workshop.

-

Tereos

Installation of a turbo-alternator in a sugar refinery-distillery.