Milk, Infant formula

Frequently Implemented Processes

- Refrigerated warehousing

- Coarse filtration

- Skimming by centrifugation

- Standardisation, pasteurisation

- Ultrafiltration, evaporation, crystallisation

- Drying, canning

- Line inspection, metal detector, camera

- High-speed filling and packaging

- Aseptic filling

- Packaging, labelling, case packing, palletising

- Clean-in-place

Some of our Achievements

-

Agropur

More than 150 projects since 2008 including capacity increase, process upgrades and energy savings.

-

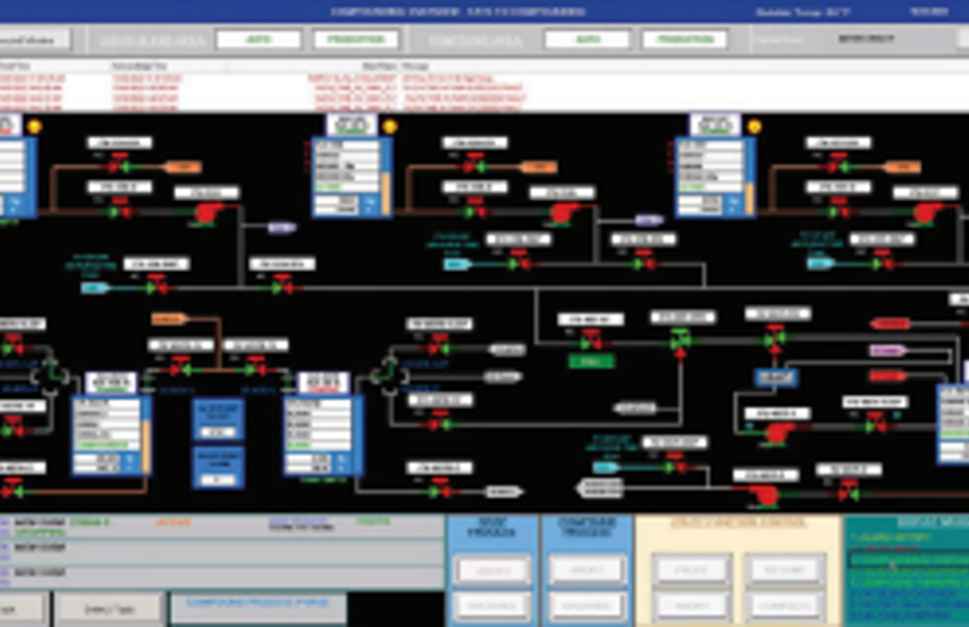

Client confidentiel

Upgrade of the process automation system in an infant formula manufacturing facility.

-

Confidential client

New liquid whey processing plant including a new centralized CIP station.

-

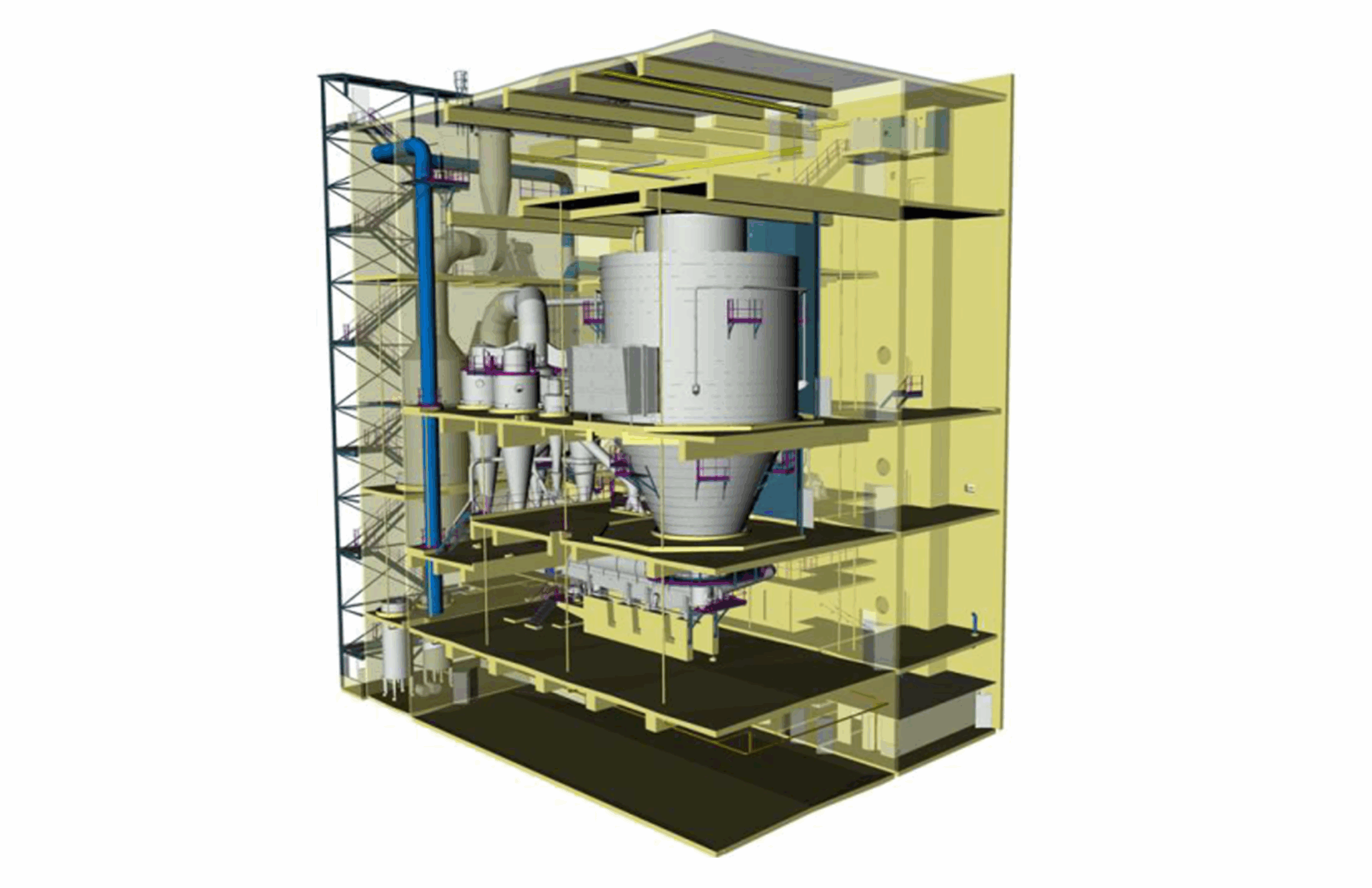

Euroserum

New building and whey atomization tower for infant milk production.

-

Fairlife

Completion of 4 plant expansion projects including filtration equipment, a new packaging system, aseptic tanks, and new wastewater treatment system.

-

Kerry

Over 25 process, packaging and utility projects at several sites, including protein drinks, oat milk and chocolate milk.