Beer, wine, spirits

Frequently implemented processes

- Handling, storage and transformation of raw materials

- Extraction

- Fermentation, distillation

- Centrifugation, filtration

- Pasteurisation, sterilisation

- Filling of carbonated or nitrogen-rich products

- Filling of flammable products

- High-speed depalletising, rinsing, filling, conveying, packaging and labelling

- In-line inspection: metal detector, checkweigher, camera

- Water and waste treatment

- Clean-in-place

- Automated warehousing

Some of our achievements

-

Andrew Peller

Numerous wine production projects: new wine bottle filler, optimisation of packaging lines and modernisation of a filling line.

-

Andrew Peller

Replacement and centralization of the entire ammonia refrigeration system at a wine plant.

-

Brasserie Wills

New microbrewery.

-

Constellation Brands

Process design for whisky production.

-

Distillerie Arsenal

Electrical and utilities engineering for a new gin plant.

-

Glutenberg

New gluten-free microbrewery.

-

Hiran Walker Distillery (Diageo)

Brownfield new packaging line and batching system upgrade for spirits production.

-

Kruger Wines and Spirits

Production volume increase, including a new packaging line (glass and PET bottles).

-

Microbreweries

Preliminary, detailed design and execution of more than 25 new microbreweries.

-

Molson Coors

More than 500 projects in all Canadian breweries in processes, utilities, CIP, ammonia refrigeration and packaging.

-

Molson Coors

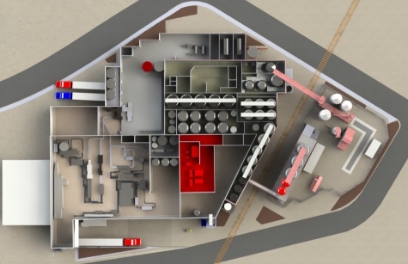

Greenfield project of a new large brewery with state of the art equipment and automation.

-

Molson Coors

New selter production unit within an existing facility.

-

Molson Coors

New hard cider production unit in an existing plant.

-

Okanagan Spring Brewery

Capacity expansion of a brewery.

-

Sleeman Breweries

Process upgrade and capacity increase of a brewery.