Water, Juice, Soft-Energy-Nutritional drinks, Tea, Coffee

Frequently Implemented Processes

- Handling, storage and transformation of liquid and solid raw materials

- Extraction, percolation, evaporation

- Fermentation

- Centrifugation, filtration, carbonation

- Roasting

- Pasteurisation, sterilisation, UHT, aseptic storage

- Blowmolding

- High-speed filling and packaging

- Aseptic filling

- In-line inspection: metal detector, checkweigher, camera

- Bag-in-box packaging

- Water and waste treatment, clean-in-place

- Automated warehousing

Some of our Achievements

-

Atoka Cranberries

Optimisation and automation of the concentrated juice process (evaporator, storage, filling, CIP, transfer matrix).

-

Coca-Cola

Over 40 projects at various plants in Canada and the United States: new bottling lines (including blow molding, filling), effluent treatment, HVAC, CIP.

-

Fairlife

Completion of 4 plant expansion projects including filtration equipment, a new packaging system, aseptic tanks, and new wastewater treatment system.

-

Johanna Foods

New smoothies fabrication process.

-

Jus Impress

Installation of a fruit and vegetable juice production plant.

-

Kerry

More than 25 process, packaging and utilities projects at several sites.

-

Lassonde

Beverage plant expansion (two facilities).

-

Minute Maid

Integration of a juice concentrate pasteuriser.

-

Nestlé Waters (Primo Brands)

Over 120 projects: filling and packaging lines (cans, PET bottles), blow molding, water treatment, flash pasteurization, mechanical and electrical utilities.

-

Rise Kombucha

Expansion of a fermented tea production plant including brewing tanks and packaging lines.

-

David's Tea

Improvement of the productivity of a tea processing plant.

-

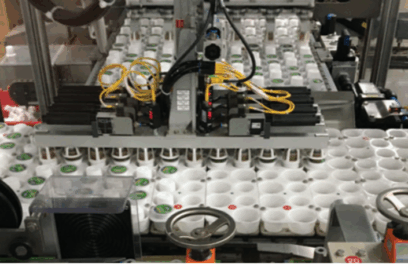

Keurig

Capacity increase of a coffee capsule plant (K-cups).

-

Kraft Heinz

Transfer of coffee capsule production to a new plant.

-

Mother Parker Tea and Coffee

New liquid coffee processing unit within an existing facility.

-

Torréfactorie

Repatriation of the entire coffee roasting process to the company’s premises to enable an increase in production and improve distribution efficiency.